|

|

Post by anneinwa on May 1, 2015 0:53:26 GMT

I have used HTV to make two tshirts for my daughter so far. Have a few girls on her softball team in love with the softball shirt, and want me to make one for them. I asked them to wait a few washes to make sure it holds up. Today my daughter told me the 'red threads of the softball' are loose in one small section. Is this possibly due to not heating it enough? It's been washed a couple times already. Can I just retack it down still?

|

|

|

|

Post by crazy4scraps on May 1, 2015 3:36:52 GMT

You can try it, you really have nothing to lose. The problem with the iron on vinyl is that it's hard to get the whole design heated long enough and pressed hard enough with a home iron. I have a shirt I made for DD with the flocked iron on stuff and noticed a corner on it coming up, so I'm in the same boat.

|

|

iowgirl

Pearl Clutcher

Posts: 4,319

|

Post by iowgirl on May 1, 2015 4:03:15 GMT

I put a piece of parchment over it and reiron.

|

|

|

|

Post by htstepper on May 1, 2015 5:07:22 GMT

I work with HTV a lot and you need to act like a heat press with your iron. I highly suggest you get a teflon sheet ($6ish) to place over your HTV as that will help the heat to be distributed evenly. You can use parchment, but I think the teflon sheet is better. Also, you need a hard surface underneath your shirt when pressing like a metal cookie sheet or I use a piece of smooth floor tile inside my shirts. You have to use lots of pressure and don't iron back and forth, just firm presses without moving and hold it in one place for about 15 seconds.

What kind of HTV are you using? I like Siser Easyweed. I would try again with your daughter's shirt with the parchment and hard, hard presses.

|

|

|

|

Post by anneinwa on May 1, 2015 16:15:01 GMT

Thanks for the replies. I will give it another try to tack that section down. I would love to make the shirts for the girls but don't want them to start falling apart.

|

|

|

|

Post by anneinwa on May 1, 2015 16:20:17 GMT

I work with HTV a lot and you need to act like a heat press with your iron. I highly suggest you get a teflon sheet ($6ish) to place over your HTV as that will help the heat to be distributed evenly. You can use parchment, but I think the teflon sheet is better. Also, you need a hard surface underneath your shirt when pressing like a metal cookie sheet or I use a piece of smooth floor tile inside my shirts. You have to use lots of pressure and don't iron back and forth, just firm presses without moving and hold it in one place for about 15 seconds. What kind of HTV are you using? I like Siser Easyweed. I would try again with your daughter's shirt with the parchment and hard, hard presses. HTV was Siser Easyweed. Love it. Ordered another Siser that was not Easyweed (holographic/shimmery) and I was cursing that and gave up. Could not get it to weed no matter what setting I used. Might checked ththecompany to see if I just got a bad piece. I did do my research and used pressure and kept it in place for at least 15 seconds. Checked and redid it again. Not sure if using too much heat can bad? I used a cutting board inside the shirt and parchment paper over the HTV. I should mention the red piece is a layered piece. Only thing it looks like I can really change right now (short of getting a press) is to try the Teflon sheet. I have a list of 3-4 more shirts I want to make! |

|

|

|

Post by htstepper on May 2, 2015 16:17:44 GMT

It sounds like you did everything right. Usually the HTV will wrinkle if it gets too hot. I have never tried that type of Siser though. I would get a Teflon sheet for future. They are pretty cheap. I got mine from ebay, but Amazon has them too! I think I paid around $6ish on ebay? Teflon sheet: amzn.to/1E4vztb |

|

|

|

Post by anneinwa on May 2, 2015 19:40:08 GMT

It sounds like you did everything right. Usually the HTV will wrinkle if it gets too hot. I have never tried that type of Siser though. I would get a Teflon sheet for future. They are pretty cheap. I got mine from ebay, but Amazon has them too! I think I paid around $6ish on ebay? Teflon sheet: amzn.to/1E4vztbThank you for that link! Just ordered it. I looked this morning and out of habit, I always clicks he prime option. They were all more than I wanted to spend. That price and free shipping is perfect! I am am guessing I did not get enough heat/pressure on that one spot. Will attempt again and also let the girls know I will repair/remake at my cost if it comes apart this season. Itching to make the other softball shirt for my daughter but will be patient till the Teflon sheet comes. |

|

|

|

Post by Basket1lady on May 3, 2015 2:07:39 GMT

I use a Teflon sheet and have had good luck. I think all I've done are layered designs. I iron over the material to get it hot. Then I adhere the first color for about 8 seconds, then the next color for about 5 seconds, and so on. Then I press the entire design for about 15 seconds. So far, so good.

|

|

|

|

Post by anneinwa on May 3, 2015 3:02:52 GMT

I use a Teflon sheet and have had good luck. I think all I've done are layered designs. I iron over the material to get it hot. Then I adhere the first color for about 8 seconds, then the next color for about 5 seconds, and so on. Then I press the entire design for about 15 seconds. So far, so good. I will try this next. This had a very small area that was layered. My next project is more layered areas. |

|

|

|

Post by htstepper on May 5, 2015 15:53:47 GMT

I use a Teflon sheet and have had good luck. I think all I've done are layered designs. I iron over the material to get it hot. Then I adhere the first color for about 8 seconds, then the next color for about 5 seconds, and so on. Then I press the entire design for about 15 seconds. So far, so good. Yes, this is what I do as well. Sometimes HTV shrinks when pressed, so I agree with barely pressing the first layer until you get the following layers on. If you are doing layered lettering, like a shadow, it sometimes looks like it does not fit properly if the first layer is pressed too much. |

|

|

|

Post by Basket1lady on May 5, 2015 16:35:44 GMT

I use a Teflon sheet and have had good luck. I think all I've done are layered designs. I iron over the material to get it hot. Then I adhere the first color for about 8 seconds, then the next color for about 5 seconds, and so on. Then I press the entire design for about 15 seconds. So far, so good. Yes, this is what I do as well. Sometimes HTV shrinks when pressed, so I agree with barely pressing the first layer until you get the following layers on. If you are doing layered lettering, like a shadow, it sometimes looks like it does not fit properly if the first layer is pressed too much. Exactly. With layered designs, you only want to heat each layer long enough to be able to peel off the clear transfer backing. I've had some designs shrink a tiny bit. Sometimes less is more! When you peel up the clear transfer sheet for the final time, watch to see that it's all adhered. If a corner pulls up a little with the removal of the transfer sheet, press the design for a few more seconds. FWIW, I've only used Cricut and Silhouette heat transfer materials. The glitter stuff is pretty cool! |

|

|

|

Post by htstepper on May 6, 2015 23:04:44 GMT

Yes, this is what I do as well. Sometimes HTV shrinks when pressed, so I agree with barely pressing the first layer until you get the following layers on. If you are doing layered lettering, like a shadow, it sometimes looks like it does not fit properly if the first layer is pressed too much. Exactly. With layered designs, you only want to heat each layer long enough to be able to peel off the clear transfer backing. I've had some designs shrink a tiny bit. Sometimes less is more! When you peel up the clear transfer sheet for the final time, watch to see that it's all adhered. If a corner pulls up a little with the removal of the transfer sheet, press the design for a few more seconds. FWIW, I've only used Cricut and Silhouette heat transfer materials. The glitter stuff is pretty cool! You should try Siser! It is very easy to work with. Much easier than both of those.  |

|

|

|

Post by Basket1lady on May 7, 2015 1:06:03 GMT

Exactly. With layered designs, you only want to heat each layer long enough to be able to peel off the clear transfer backing. I've had some designs shrink a tiny bit. Sometimes less is more! When you peel up the clear transfer sheet for the final time, watch to see that it's all adhered. If a corner pulls up a little with the removal of the transfer sheet, press the design for a few more seconds. FWIW, I've only used Cricut and Silhouette heat transfer materials. The glitter stuff is pretty cool! You should try Siser! It is very easy to work with. Much easier than both of those.  What makes it better? I can't imagine anything easier than what I'm using. I hear it weeds easier, but again, the other stuff weeds so easy. |

|

|

|

Post by anneinwa on May 7, 2015 3:58:15 GMT

I use a Teflon sheet and have had good luck. I think all I've done are layered designs. I iron over the material to get it hot. Then I adhere the first color for about 8 seconds, then the next color for about 5 seconds, and so on. Then I press the entire design for about 15 seconds. So far, so good. Yes, this is what I do as well. Sometimes HTV shrinks when pressed, so I agree with barely pressing the first layer until you get the following layers on. If you are doing layered lettering, like a shadow, it sometimes looks like it does not fit properly if the first layer is pressed too much. Aside from that is there much of a learning curve with layering letters? My daughter and her friends have a club in which they are raising money for a charity. One of the girls designed a shirt but the company she looked at wanted like $26/shirt. So my daughter says "my mom has this cool machine. Look at the shirt she made me!" Lol. So might be making those too. |

|

|

|

Post by htstepper on May 7, 2015 16:35:04 GMT

You should try Siser! It is very easy to work with. Much easier than both of those.  What makes it better? I can't imagine anything easier than what I'm using. I hear it weeds easier, but again, the other stuff weeds so easy. It cuts and adheres nicely. I have heard of Silhouette brand peeling off, but that could be user error. I can also get Siser cheaper, inch per inch. |

|

|

|

Post by htstepper on May 7, 2015 16:37:35 GMT

Yes, this is what I do as well. Sometimes HTV shrinks when pressed, so I agree with barely pressing the first layer until you get the following layers on. If you are doing layered lettering, like a shadow, it sometimes looks like it does not fit properly if the first layer is pressed too much. Aside from that is there much of a learning curve with layering letters? My daughter and her friends have a club in which they are raising money for a charity. One of the girls designed a shirt but the company she looked at wanted like $26/shirt. So my daughter says "my mom has this cool machine. Look at the shirt she made me!" Lol. So might be making those too. Are you using a Silhouette? You can turn the cut lines on and off for each layer so you can cut one layer at a time. Just browse around Youtube and I'm sure there is a video that explains that. I find it easier to layer with HTV than adhesive vinyl since you can move the HTV easier around before you press each layer. Just don't forget to mirror your entire design and cut with the shiny side down on your mat. |

|

|

|

Post by Basket1lady on May 7, 2015 22:42:06 GMT

It's easy to use, but I'm not sure how cost effective it would be to mass produce shirts. It's not cheap, and if you mess up (like forget to mirror image!), that material is wasted. Check around at the local printing companies. They do tees all the time for soccer teams and such. A single color tee should be under $10, less if you are ordering a ton. The price will go up with each color added. But we just ordered tees from a local company for the musical, 2 colors. We ordered around 100 and paid about $8 each for them. The company is in Fairfax, Virginia (not sure that matters!)

|

|

|

|

Post by Basket1lady on May 7, 2015 22:45:05 GMT

Aside from that is there much of a learning curve with layering letters? My daughter and her friends have a club in which they are raising money for a charity. One of the girls designed a shirt but the company she looked at wanted like $26/shirt. So my daughter says "my mom has this cool machine. Look at the shirt she made me!" Lol. So might be making those too. Are you using a Silhouette? You can turn the cut lines on and off for each layer so you can cut one layer at a time. Just browse around Youtube and I'm sure there is a video that explains that. I find it easier to layer with HTV than adhesive vinyl since you can move the HTV easier around before you press each layer. Just don't forget to mirror your entire design and cut with the shiny side down on your mat. When I layer colors of vinyl, I drag the images that I'm not using off the mat, arrange the colors that I am using and group everything. Then I cut the 1st color, drag that off, and then drag on the next color and cut that. I use the fill function to color in my design/letters so that I don't get mixed up. I've also set up separate cut files for each color, but the drag on & off is just as easy, and if I zoom out, I can see everything on one page. It helps me keep track of stuff better. I know I'd forget to turn off or on a cut line and mess up the entire cut! |

|

|

|

Post by anneinwa on May 8, 2015 18:59:55 GMT

It's easy to use, but I'm not sure how cost effective it would be to mass produce shirts. It's not cheap, and if you mess up (like forget to mirror image!), that material is wasted. Check around at the local printing companies. They do tees all the time for soccer teams and such. A single color tee should be under $10, less if you are ordering a ton. The price will go up with each color added. But we just ordered tees from a local company for the musical, 2 colors. We ordered around 100 and paid about $8 each for them. The company is in Fairfax, Virginia (not sure that matters!) There is like 6-8 kids so not a huge deal. I figure it will give me a chance to learn more as well as practice it. It would be a silhouette of dog/cat in the middle with their club name above and below. Originally design had layered letters so I will probably give that a shot. Will have them pickup their own shirt (making sure that they get a size that fits) and then charge just for materials. |

|

|

|

Post by anneinwa on May 8, 2015 19:02:31 GMT

As for layering, I was more curious in the application. Using the program/machine does not worry me, although I am sure I will forget to mirror at some point! I forgot the HTV does work different than non HTV, so that is probably why I was worried at first. Should be a breeze, with a little practice.

|

|

|

|

Post by Basket1lady on May 8, 2015 20:33:03 GMT

As for layering, I was more curious in the application. Using the program/machine does not worry me, although I am sure I will forget to mirror at some point! I forgot the HTV does work different than non HTV, so that is probably why I was worried at first. Should be a breeze, with a little practice. It really is easy. The HTV is on clear vinyl. Once you weed the design, you have complete clarity to line up your design. I layer letter and images a lot and it's so easy. Unlike layering vinyl, the tack on the clear transfer plastic is very low. You can reposition the design as much as you need to and it's not permanent until you add heat. I've forgotten to mirror image my design before, and I even have a post it sticky on my Cameo to remind me. That's what happens when you are in a hurry! |

|

scrapalatte

Shy Member

Posts: 24

|

Post by scrapalatte on May 9, 2015 11:24:16 GMT

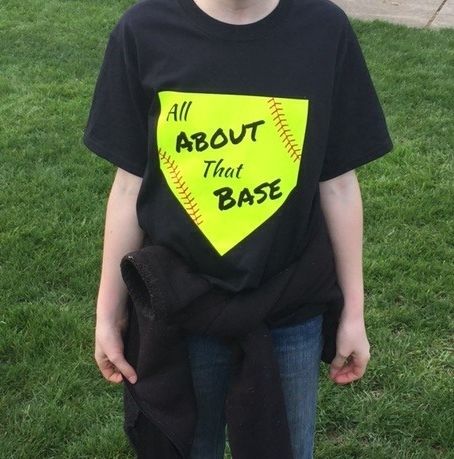

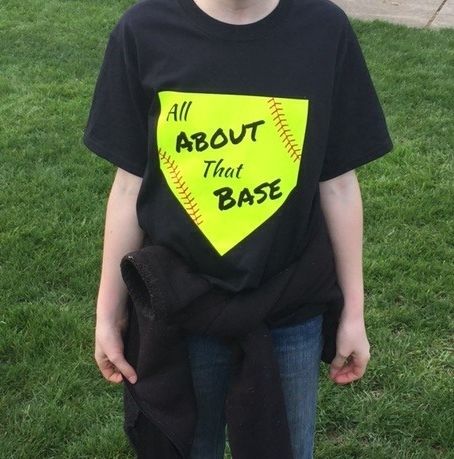

Can you post a pic of your softball shirt? I'd love to see it!

|

|

|

|

Post by anneinwa on May 9, 2015 16:33:50 GMT

Can you post a pic of your softball shirt? I'd love to see it! Will do soon. What is the best way? It's been too long since I have posted a picture on a MB. |

|

scrapalatte

Shy Member

Posts: 24

|

Post by scrapalatte on May 10, 2015 1:52:09 GMT

Can you post a pic of your softball shirt? I'd love to see it! Will do soon. What is the best way? It's been too long since I have posted a picture on a MB. I have no idea... |

|

|

|

Post by anneinwa on May 10, 2015 2:22:58 GMT

Can you post a pic of your softball shirt? I'd love to see it! Let's see if this works... The next one I want to do is a silhouette of her pitching over a softball... Was going to use her silhouette from last year but realized her form has change a lot in the past year... So time to look through photos for the right pose.  |

|

scrapalatte

Shy Member

Posts: 24

|

Post by scrapalatte on May 10, 2015 2:26:40 GMT

Can you post a pic of your softball shirt? I'd love to see it! Let's see if this works... The next one I want to do is a silhouette of her pitching over a softball... Was going to use her silhouette from last year but realized her form has change a lot in the past year... So time to look through photos for the right pose.  That is awesome! Thanks for posting! |

|